Biodegradable Kraft Paper Bag model: BTG-20

Biodegradable Kraft Paper Bag model: BTG-20

Product Introduction

The kraft paper bag is based on all-wood pulp paper. The color is divided into white kraft paper and yellow kraft paper. A layer of PP film can be used on the paper to play a waterproof role. The strength of the bag can be made into one to six layers according to customer requirements. printing and bag making integration. The opening and back cover methods are divided into heat sealing, paper sealing and paste bottom.

The production of kraft paper ziplock bags is mainly used for composite production process: the window kraft paper ziplock bags are mainly made of kraft paper, PE film (using ordinary equipment to make clip chain ziplock bags), matte frosted film, and these materials are pressed together through a composite process. At the same time, a beautiful and elegant composite bag packaging bag with frosted visibility is formed.

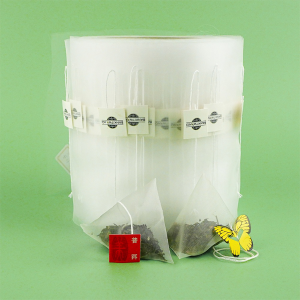

Our airtight packaging is the perfect choice to keep delicate tea leaves fresh until they reach your customer’s cup. Collection available in white and kraft paper. keeps your products fresh and keeps unwanted moisture and odors out. Heat-sealed bags extend product shelf life, maintains freshness, and ensures food safety. All of our bags are safe for direct contact with food. Made of biodegradable material.It can be degraded quickly and completely under natural conditions. Fully biodegradable resin ,Based on kraft paper,harmless to the environment,Composted into organic fertilizer,Fully degradable product,Fully degradable in about three months under industrial composting conditions,In the natural environment, it is related to temperature and humidity,it may take 1-2 years for full degradation.

Product Parameters

| Model | BTG-15 | BTG-17 | BTG-20 |

| Specification | 15*22+4 | 17*24+4 | 20*30+5 |

| Dried beef | 180g | 250g | 600g |

| sunflower seeds | 200g | 320g | 650g |

| Tea | 180g | 250g | 500g |

| white sugar | 650g | 1000g | 2000g |

| Flour | 250g | 450g | 900g |

| Wolfberry | 280g | 450g | 850g |